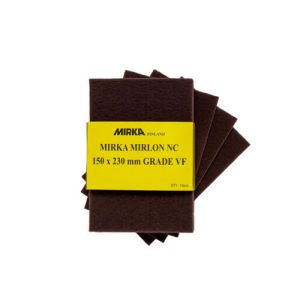

Non-Woven Abrasives

Non-woven abrasives are surface finishing materials made from nylon fibres bonded with abrasive grains. Unlike traditional coated abrasives, they are flexible, conform easily to uneven surfaces, and provide a consistent finish without changing workpiece dimensions.

With their flexibility, durability, and reliable performance, non-woven abrasives in Malaysia are widely used in automotive repair, woodworking, and metal fabrication. They are especially valued for cleaning, polishing, deburring, and finishing tasks where precision and uniformity are critical.

Sohadu offers high-quality non-woven abrasives ideal for cleaning, finishing, and surface conditioning across various industries. Made from tough nylon fibre webs embedded with abrasive grains, these products are designed to conform to uneven surfaces and deliver consistent results. Whether you’re working in automotive repair, woodworking, or metal fabrication, non-woven abrasives provide reliable performance for tasks like matting, blending, deburring, and rust removal.

As a trusted abrasive supplier in Malaysia, Sohadu ensures quality and durability in every product we supply.

Showing all 2 results

Advantages of Non-Woven Abrasives

Industries often prefer non-woven abrasives because of their unique benefits compared to traditional abrasives:

- Dimensional Integrity – They do not alter the original shape or thickness of the workpiece.

- Non-Loading Design – Prevents clogging, even during extended use.

- Consistent Finish – Delivers uniform results across the entire surface.

- Flexibility – Adapts to contours and complex shapes for smooth finishing.

- Durability – Long-lasting materials ensure reliable performance.

These advantages make non-woven abrasives the go-to choice for professionals who demand precision and efficiency.

Why Choose Our Non-Woven Abrasives?

- Three-dimensional web structure for better surface contact and flexibility

- Non-loading design and heat-resistant materials

- Suitable for hand use or machine application

- Excellent for surface prep, blending, and light deburring

- Long-lasting with a consistent, uniform finish

Our non-woven abrasives help professionals achieve smooth, accurate results with minimal clogging or wear.

Common Applications

Non-woven abrasives are used in a wide range of finishing and cleaning tasks, such as:

- Paint preparation and surface matting

- Rust, scale, and oxidation removal

- Blending welds and smoothing edges

- Cleaning delicate or contoured surfaces

- Final finishing of stainless steel, aluminium, and composite materials

They are especially valued for their ability to condition surfaces without altering dimensions.

Related Products

Looking for more surface finishing solutions? Sohadu Industries offers a complete line of high-quality abrasive products:

- Abrasive Paper – Ideal for precise sanding and polishing tasks

- Abrasive Cloth (Cotton) – Durable and flexible for industrial sanding

- Polyester Cloth – Heat-treated, durable abrasives for demanding use

- Specialty Abrasives – Tailored for unique or high-precision industrial applications

Achieve the Perfect Surface Finish with Premium Non-Woven Abrasives

Whether you’re in automotive, woodworking, or metal fabrication, our non-woven abrasives deliver consistent performance on even the most complex surfaces. Trust Sohadu for durable, efficient, and professional-grade surface conditioning solutions.

Need help selecting the right product or looking for a custom quote? Contact Us today!

Frequently Asked Questions (FAQ)

What is the difference between non-woven and coated abrasives?

Coated abrasives use a flat backing like paper or cloth, while non-woven abrasives are made of nylon fibre webs with abrasive grains. Non-woven products are more flexible and provide consistent finishes without altering dimensions.

Can non-woven abrasives be used on stainless steel?

Yes. Non-woven abrasives are widely used for finishing stainless steel surfaces, especially for blending welds, removing oxidation, and achieving smooth, uniform finishes.

Are non-woven abrasives reusable?

Yes, non-woven abrasives can often be reused multiple times depending on the application. Their durable, non-loading design allows for extended use before replacement is needed.

Which industries use non-woven abrasives most?

They are commonly used in automotive refinishing, woodworking, metal fabrication, aerospace, and general manufacturing. Many industries in Malaysia rely on non-woven abrasives for reliable, high-quality surface preparation.